Over the past few months, we have received submissions from

professional luthiers, beginner Do-It-Yourself-ers, and everyone in

between. With all of the love that we recevied, we decided to

highlight 5 of our favorite submissions, who did them, what

products and processes they used, and a photo of the finished

project.

Feel free to submit us your recent projects (as well as the

products you used on it) to qualify yourself to be in our next

blog! Submit your photos on our Facebook, Twitter, Pinterest, Instagram, or using our hashtag,

#MohawkConsumer

#1 - Mid-1950s Framus Cello Refurbishment

Completed by: American

Toolbox

Products used: Behlen Violin Varnish, Behlen Rottenstone, and Behlen Hide Glue.

The Process: "Received a damaged cello. Removed top,

repaired various cracks, reglued top with Behlen Hide Glue.

Extensive finish damage. Purchased Behlen Violin

Varnish, diluted with denatured alcohol, tinted with old collection

of pigments. Learned 57 ways not to apply varnish. Used

Behlen Wool Lube and Rottenstone extensivly

between coats and at completion. More images at www.nakedluthier.com"

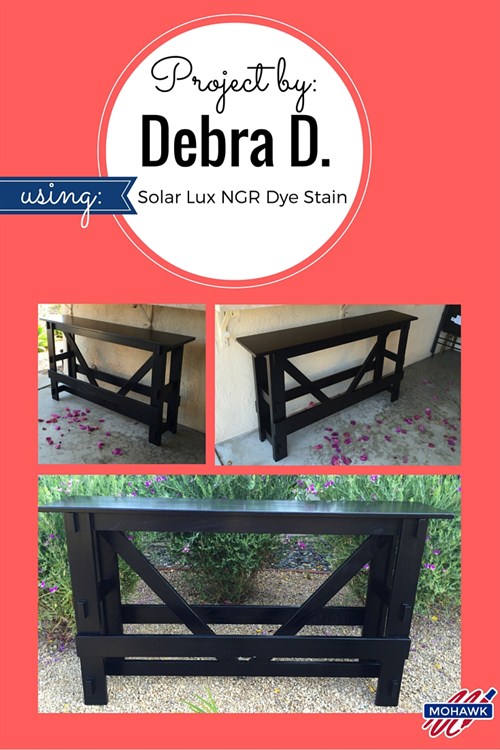

#2 - Table Staining

Completed by: Debra D.

Products used: Jet Black Solar-Lux NGR Dye Stain

The Process: "I made this bar height backless bench for my son's

outdoor bar. It has a 30" seat height. Made from red oak.

After assembly, a fine sand using 220 grit. 3 coats of

your Jet Black Solar Lux NGR Dye Stain. Using the finest

steel wool, lightly go over the first coat only. Then, I used

Old Masters Wiping Stain, Spanish Oak to really turn it ebony.

2-3 coats on top of the dye. Finished using Old Masters

water based Spar Urethane for outside protection. I used

quality 1 and 2 inch foam brushes to apply all the dye, stain, and

finish."

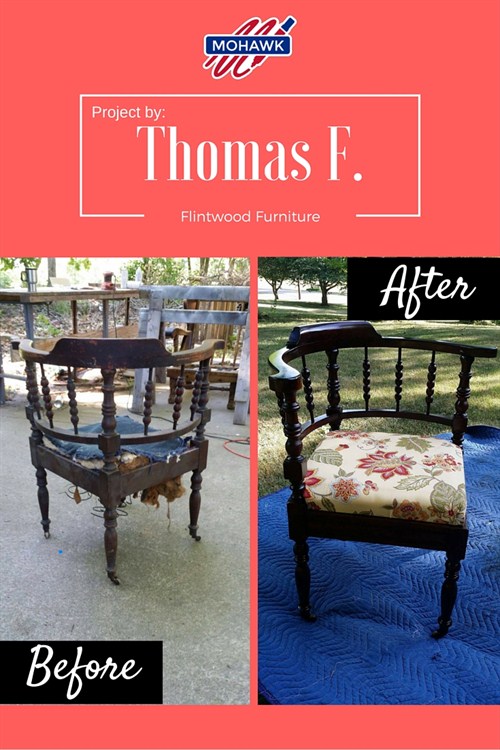

#3 - Chair Makeover

Completed by: Thomas F. of Flintwood Furniture

Products used: BurgundyStain with a Dark Red Walnut tinted Lacquer (Ultra Classic

Toner), and it was finished with Tone Finish Clear (Satin).

The Process: "First, I stripped it down by sanding it 3 times.

1st with 60 grit, then with 100 grit, then with 150 grit.

Then, I vacuumed it with a shop vacuum. Then, I washed

it off with Mohawk Naphtha, applied stain, let it dry for 2 hours,

sprayed 2 coats of lacquer, adn sanded again with 400 grit sand

paper. I tinted it with Mohawk Dark Red Mahogany Ultra

Classic, then finished it off with 1 more coat of Mohawk Satin

Lacquer."

#4 - Finishing Done by a Luthier

Completed by: Jesse Ian

H.

Products Used: Classic Instrument Lacquer, E-Z Vinyl Sealer Medium Solids, and Lacquer Reducer 2255.

The Process: "My process is: Prep sand to 220 grit then 3-4

coats vinyl sealer. Apply grain filler and apply 1 more coat

of sealer. Then, spray 8 coats of clear lacquer reduced 50%.

Level sand to 220 grit and spray color coat. Then, 12 coats

of clear lacquer reduced 50% with thinner. Wait 1 week and

wet sand with 1200 grit and buff."

#5 - Before & After - Table Edition

Completed by: Curtis G. of

Curtis Glover Creative

Products Used: Designer Stain Radiant Series Golden Brown

Stain with a Satin 40 Lacquer Finish.

The Process: "Took 60 grit sandpaper to get the previous stain

off, hand planed the top to eexpose the character in the wood, 120

grit to smooth out rough edges, then 300 to give it that smooth to

the touch finish. Stain took well to raw wood and sealed it

with the satin finish, multiple overcoats on tabletop surface for

durability purposes."

We would love to see what you are working on: submit us your

photos at Facebook or Twitter!