Our October Guitar of The Month winner is David

Paetow! He built a super unique guitar and is ready to

share it with us. Read on to hear David explain why he prefers this

style of build and how he finished it!

"I like to travel, and bring a guitar along with me on trips. I

had a couple of Steinbegers, even though they were small and

indestructible. I never bonded with the tone of them, plus they are

rather heavy for how small they were. So a few years ago I decided

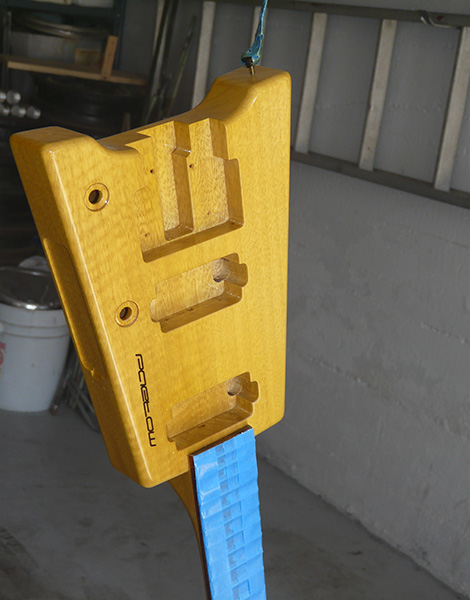

to build a lighter weight headless guitar. I chose African Limba

wood, otherwise known as 'Korina'. Since I have been wrenching on

guitars for 30+ years, I knew it was within my abilities to create

this guitar. I'll spare you the details about actually building it,

but basically it is a Steinberger body shape but with a 22 fret

neck instead of 24. It uses a Steinberger bridge and headpiece, and

the electronics out of a PRS Custom with a rotary 5 way switch.

Now onto the finish work! I'm trying not to be long winded here

to bore everybody, so I will get to the point. Since there is a Rockler

woodworking store near me, it's handy to buy Behlen products,

so that is what I used. Once I had the guitar built, I did all the

finish sanding, raising the grain, and eventually worked my way up

to 320 grit, making sure all the sanding marks were gone. Then I

pore filed the guitar, and re-sanded with 320 to make sure it was

ready for paint. Then I shot a couple coats of Behlen Sealer over the whole guitar. I

let that cure, sanded that with 320 until everything was smooth,

then shot a coat of very thinned out Behlen Stringed Instrument lacquer and let it

sit for a couple days. I examined the guitar carefully at that

point to make sure the guitar was sealed and very smooth. Then I

proceeded with the color coats.

I wanted to replicate the color used on old Gibson Korina V's

and Explorers from the 1950's, so I wanted an amber finish on it. I

again used very thinned out Behlen Stringed Instrument Lacquer, added some

amber tint, and used my trusty door jam spray gun to shoot the

color coat. I let that sit for a day and examined it to make sure I

was satisfied with the color. I decided it need a little more tint,

so I shot another light coat, and then I was satisfied. Then I shot

the clear coats.

I think I shot 3 or 4 clear coats on the guitar. Then I let it

sit for a day, did some scuff sanding to get rid of any orange

peel, then applied the water transfer decal. Once the decal was

dry, I shot a couple of light clear coats over the decal. I let it

sit for a day. Then I shot the rest of the clear coats. I think I

did 4 coats a day, then let it sit for a day, then I scuff sanded

it, to level out where the decal was placed, at that time I then

shot the final clear coats. After that, I let the guitar hang for a

month to cure. I like to let the finish cure for as long as

possible, so the finish hardens up before hitting it with the

buffing wheel. Then it was wet sanded and buffed out. I

assembled it, and It turned out really nice, and has traveled with

me all over the USA!"

Thanks for sharing this with us, David! If you have any

questions about the guitar, our products, or anything else, feel

free to reach out.

If you would like to be considered for our Guitar of the Month

for November, submit your before and after photos on our Facebook

page or group, or tag us on Instagram. See

you next week!